A Look at Impossible Foods’ Water Footprint in 2019

(Impact Report 2019)

OUR WATER FOOTPRINT

As a California-based company, we’re acutely aware that water is precious. We’re also determined to keep our own footprint as low as possible, which supports long-term business resilience.

REUSE AND RECAPTURE: WATER USE IN MANUFACTURING

Clean-in-Place (CIP) is a common process in food and beverage manufacturing, critical to production and food safety. It allows operators to clean tanks, pipes, and general processing equipment without having to take everything apart and reassemble after a manual cleaning. As a process, it saves a lot of time, money, and chemicals compared to doing everything by hand. It also provides ways to recapture and recycle – which gets us closer to closing the loop on water use.

We’re replacing our 2016 CIP equipment with more efficient equipment. Time, flow, temperature, and level of cleaning chemicals can all be adjusted, but the most important step is recapturing the CIP output: Collect the water and solvents, filter them, and reuse the resulting clean water. This investment in an infrastructure update saves on water costs and chemical costs over the longer term.

Engineering projections show that we should see more water saved than discarded with the new CIP process, at a ratio of 3:2. This is a huge improvement over our prior system, which had no recycle capacity. Likewise, we’ll improve our chemical-efficiency use significantly, with a projected ratio of 3:1 for recovered cleaning chemicals to discarded cleaning chemicals.

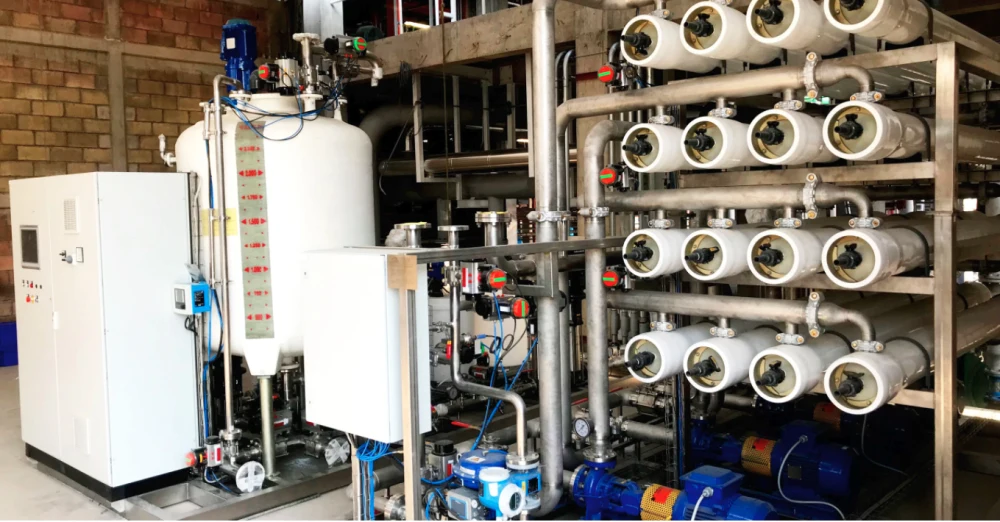

Reverse osmosis engineering initiative to increase water savings and build climate resilience into operations

Old CIP System vs. New CIP System Tanks

WATER USE INNOVATIONS FOR HEME

We’re always getting better at making heme. Every year, our production yield of the “magic molecule” for meat flavor improves significantly. Yield is the single biggest determinant of input use like water; the more leghemoglobin we get out of a fermentation run, the lower the respective impacts across water and energy (see: LCA)

Earlier this year, anticipating the large increases in production required for national accounts like Burger King, we doubled down on investing in water conservation to save resources and costs, including a reverse osmosis method implemented by our heme process engineering team to capture and reuse the water without compromising production or yields.

We produce heme via fermentation in large batches, similar to the way Belgian beer is made. After fermentation is complete, the protein is separated from the yeast and fermentate. Separation requires clean water to isolate the target heme protein before being used as the key ingredient in the Impossible Burger.

That’s where reverse osmosis comes in: rather than introducing constant fresh water, reverse osmosis allows us to implement a continuous re-use of much of the necessary water. Once fully operationalized, reverse osmosis is projected to save over 30% of the total process water, with minimal change in energy use. To share these learnings, Impossible Foods is partnering with the UN Development Program to develop this project as a case study to support others in water use reduction strategies.